Painting Automation

Implementation of a customized Automatic Painting solution at one’s end provides benefits like costly paint saving, timesaving, labour saving, increased productivity, increase in production and enhanced quality of spray finish.

Our commitment revolves around tailoring automatic painting machines to match our client’s specific needs, ensuring an optimal spray painting solution. Our team of seasoned professionals oversees the customization process, guaranteeing precision and expertise at every step.

Beyond delivering top-tier auto painting systems, we extend comprehensive support by offering tailored painting solutions. We guide our customers, recommending the most suitable and cost-effective approach for their unique spray painting applications. We aim to provide not just a product but a complete, personalized solution that exceeds expectations.

Application Areas:

1] Automobile Industry

2] Defence

3] Drums & Barrel

4] General Engineering

5] Leather Industry

6] Metal

7] Heavy Engineering

8] Ceramic Industry

9] Wood / Plastic

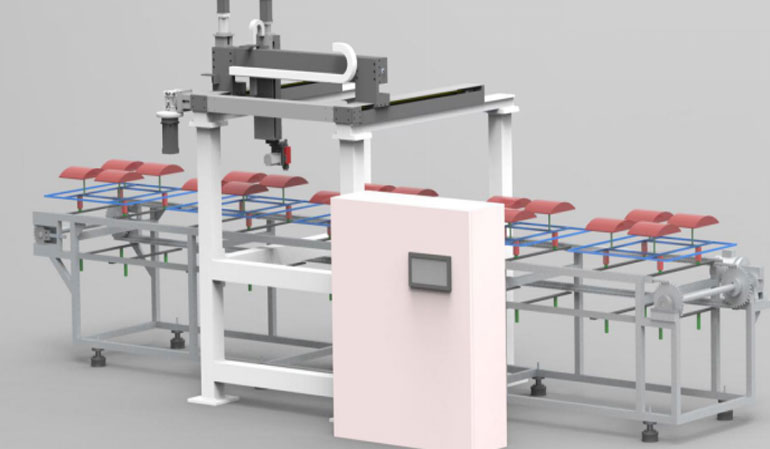

Axis machines

Experience unparalleled efficiency in coating applications with our advanced multi-axis systems, for automatic job coating. Engineered with precision, our system boasts a comprehensive range of functionalities: a two-axis linear motion (X-axis for horizontal movement, Z-axis for vertical movement) combined with a rotary B-axis capable of a 180-degree angular sweep.

Customizable linear axis lengths ensure adaptability to diverse job requirements, allowing for swift and uniform coating within seconds. Equipped with Bullows Auto Gun technology renowned for its fine atomization and compatibility with various paint types, our system guarantees exceptional results.

For seamless operations, our setup includes a PLC and HMI-based control panel, enabling full automation. Save and access over 500 unique recipes effortlessly, ensuring consistent and precise coatings across projects. Elevate your industrial coating processes with our cutting-edge, highly efficient system.

Overhead conveyor

system

Revolutionize your painting automation with our overhead conveyor system. Engineered for seamless integration into paint lines, this innovative system optimizes efficiency and precision in product coating. By suspending components overhead, it maximizes floor space while ensuring a smooth, continuous workflow.

Our overhead conveyor system streamlines the movement of products through various stages of the painting process, from pre-treatment to coating and curing. Its adaptable design accommodates diverse product shapes and sizes, offering flexibility in handling a range of items.

With precision control mechanisms, it ensures consistent and uniform paint application, resulting in high-quality finishes every time. Experience enhanced productivity and quality in your painting automation with our state-of-the-art overhead conveyor system, designed to elevate your manufacturing processes to new heights.

Reciprocator based

system

Introduce precision and efficiency into your painting automation with our reciprocator-based system. Engineered for seamless integration into painting lines, this cutting-edge technology offers a dynamic solution for uniform and flawless paint application.

The reciprocator’s controlled back-and-forth movement ensures consistent coverage across varied surfaces and shapes. Its adjustable speed and stroke length cater to diverse production needs, providing flexibility while maintaining precision. This system significantly reduces manual labour and high-speed painting capabilities for increased productivity.

From automotive parts to intricate components, our reciprocator-based system delivers impeccable results, optimizing coating efficiency and enhancing the overall quality of finished products. Elevate your painting automation with this state-of-the-art technology that ensures consistent, high-quality finishes with every stroke.